THE MOST USUAL PROBLEMS IN SEWER LINES IN FOOD, SMITHERY, MUNICIPAL AND OTHER INDUSTRIES, IN THEIR WASTEWATER TREATMENT PLANTS, AND THEIR SOLUTION

PROBLEM 1.- CLEANING THE INTERIOR SEWER LINES OF THE FACTORIES, MUNICIPAL SEWERS AND WWTP PRE-TREATMENT

INTRODUCTION

One of the main problems generated in food industries, retaurants, hotels and also in municipal cleaning networks, is that of fat, oil and protein remains (fibers, blood, etc). These difficult the performance of the equipment of the treatment plants. The solution to these problems are treatments using adapted specific microorganisms BACTERIA-BIOPOP.

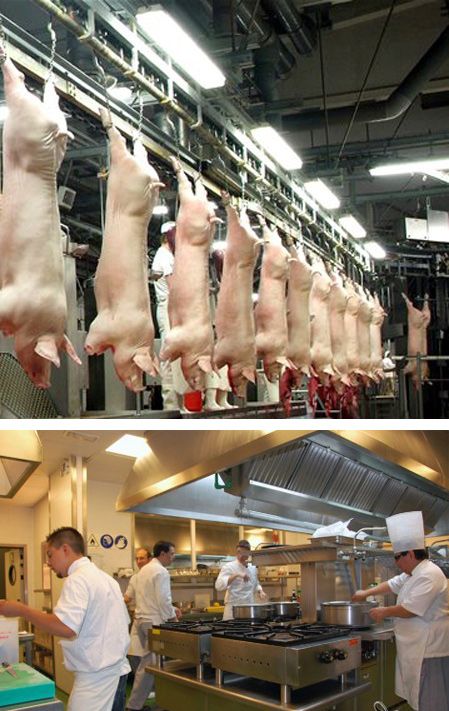

Slaughterhouses, quartering rooms, canned and pre-cooked food industries, kitchens of restaurants and hotels, and municipal sanitation networks, all have the same problem: the fat and proteins originated in these processes and also the fat and oils that reach the municipal networks of domestic origin. These products clog the drain pipes of the factories, the grease traps and municipal sewers, blocking them and producing odours. Further on, they get in the treatment plants equipment, difficulting its performance and causing a number of breakdowns. Finally, when they get to the treatment plant, they produce inhibition in the biological process and difficult BOD elimination.

ELIMINATION OF ACCUMULATED FAT AND PREVENTION OF NEW DEPOSITS

The problem is easy to solve now by installing the BACTERIA BioPop cartidges in the drains, grease traps and pipes.

The BACTERIA-BIOPOP are rugged, semi-submersible cilinders that slowly dissolve into the wastewater flow, are resistant and release the microorganisms and enzimes they contain, gradually reducing the odours and eliminating fats and oils.

HOW THE BACTERIA-BIOPOP IS LIKE

The BACTERIA-BIOPOP is maufacturated on a slow dissolving matrix inside a resistant porous netting, designed to be dissolved in any place that contains water (grease trap, pumping station, etc), or directly in a sewer line. The BACTERIA-BIOPOP is subjected with a thin rope to any item of the well, grease trap or tube, always making sure it is submerged in the water to treat.

It is manufacturated in many sizes so it can be adjusted to places of many sizes and flows (pumping wells, traps, drain and sewer lines, etc). These cilinders have a life expectancy between 30 and 90 days, depending of the system size, the water temperature and the flow speed.

|

HOW THE BACTERIA-BIOPOP IS USED BACTERIA products are easy to use and reduce significantly the operation costs of the plants, avoiding emergency interventions if they are used on a preventive manner to keep clean the level controls, pumps and any electromechanical compound installed in the treatment plants. BACTERIA-BIOPOP is specially formulated for the use in: – Food industry |