FAT AND GREASE, MINERAL OIL CONTROL IN A BIOLOGICAL WWTP – Case study

FAT AND GREASE, MINERAL OIL CONTROL IN A BIOLOGICAL WWTP – Case study

A company has a biological treatment plant that did not reach the results of depuration for elimination of COD and NTK. This manufacturing plant discharges its treated wastewater into a protected mountain river, but it is not able to meet its wastewater discharge quality requirements. After many essays and modifications of the plant performed by other companies, ATI-IN S.L. is able to solve this problem by using BACTERIA® microbial products to diminish the impact of excessive discharges on the plant.

INTRODUCTION

The problem was described to a company that belongs to the same group as BIOLOGÍA Y FILTRACIÓN S.L, ATI-IN, and they proposed to do a comprehensive audit on the wastewater sources in the manufacturing plant to determine if any of those sources were responsible for the out-of-compliance performance of the wastewater treatment system. It came as a surprise that only the sanitary facilities and showers had been considered as sources of contamination to be treated in the design of the treatment system. ATI-IN S.L proposed to examine and document all the possible sources of wastewater contamination including the employee’s food kitchen and the waste traps for mineral oils under each production machine, that had not been considered due to their low discharge volume. The audit found significant contributions to the wastewater plant load from these sources that had been overlooked.

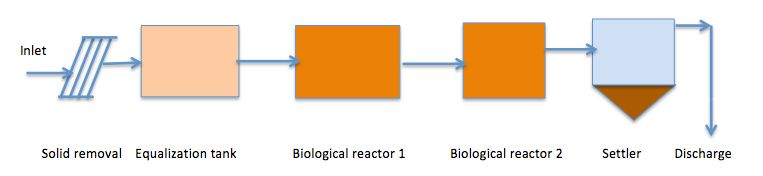

Treatment Plant

The treatment plant consists of a solids removal system followed by an equalization tank and the two adequately sized and aerated aerobic biological reactors in series using the flo-get system.

Product Application Program

Based on the audit, emphasis was placed by ATI-IN, SL on controlling the discharges coming from the employee kitchen containing oils, fats and detersives, and also on the mineral oil sources from the manufacturing plant. These loadings on the plumbing system were causing not only the inhibition of bacterial activity in the biological system, but also blockages and odors that spread throughout the production facility.

The next step consisted in NTK elimination. This problem was solved with the addition of BACTERIA – HX(3) in order to increase the bacterial action in the first biological reactor, thus improving nitrification; and at the same time BACTERIA – XNL(4) was added to the second biological reactor to improve denitrification. BACTERIA® XNL contains the Nitrosoma and Nitrobacter strains needed to oxidate the ammonia to nitrates, from which is then transformed into gas nitrogen and exits the system without contaminating the discharge flow.

Results

- Reduction of fats and oils before the biological reactor improved biological activity.

- The addition of BACTERIA in the first biological reactor improved nitrification in the system.

- The addition of BACTERIA XNL in the second biological reactor improved denitrification.

This program was very cost effective for:

- Pretreating and reducing fats, oils and greases before they entered the treatment plant,

- Improving the hydrocarbon degradation in the first biological reactor, and

- Improving the ammonia reduction in the second biological reactor, resulting in

- Thereby bringing the overall treatment plant into compliance with the discharge requirements for the plant at a reasonable cost.

Products used in the final solution

1.- ARCS SYSTEM

2.- BIOPOPS

3.- BACTERIA® HX

BACTERIA® HX biological product is a specialized blend of natural, preselected, adapted microorganisms (aerobic and anaerobic bacteria) on an active carbon support.

The main effect of nitrification is the transformation of ammonia nitrogen into nitrite and nitrate by nitrification bacteria (Nitrosomas and Nitrobacter) with oxygen presence.

Nitrosoma bacteria transform ammonia into nitrite and Nitrobacter bacteria transform it into nitrate. Nitrification is an autotroph process, that means bacteria obtain energy for their growth from the oxidation of nitrogen compounds, mainly ammonium.

The reactions that happen can be approximated in the following scheme:

NITROSOMAS

![]()

Where C5H7O2N represents the composition of a bacteria cell.

NITROBACTER

![]()

4.- BACTERIA XNL

BACTERIA XNL/XNC is an specialized liquid blend of preselected microorganisms (Nitrosomas and Nitrobacter) which are very efficient at elimination the ammonium ion (NH4+) in biological treatment plants.

Denitrification transforms nitrate to gas nitrogen under anoxic conditions. It is the second step in the nitrogen elimination processes by biological methods. The bacteria that can perform this conversion are: Achromobacter, Aerobacter, Alcaligenes, Bacillus, Brevibacterium, Flavobacterium, Lactobacillus, Micrococcus, Proteus, Pseudomonas and Spirillum. Denitrificant bacteria obtain energy from the conversion of nitrate to gas nitrogen, but being heterotroph require an income of organic matter for the synthesis of new cells; if there is not enough in the wastewater, a product containing carbon has to be added to the system.

Denitrification takes place in different stages:

![]()

The last three products are gases and are eliminated by dispersion into the atmosphere. In the denitrification systems the critical parameter is oxygen, since its presence inhibits the enzyme implicated in the denitrification reactions. The optimal pH range is between 7 and 8.

The elimination of nitrogen from the wastewaters by biological means is a widely tested system with proven effectiveness. Nevertheless, industrial wastewater do often present substances which inhibit bacterial activity. If these substances are not present and all the other conditions are met, nitrification should start by itself. In cases of toxicity and in low temperature conditions, the growth rate of the nitrificant microorganisms tends to diminish considerably, but the addition of BACTERIA HX and BACTERIA-XNL restores the population and the performance is improved.