Textile industry – SUCCESS CASE OF PLASTIC MEDIA BIOFILL® TYPE A

Textile industry – SUCCESS CASE OF PLASTIC MEDIA BIOFILL® TYPE A

Textile industry in general has different grades of contamination since it depends on the sector (dying, finishing, printing, etc) but a common feature in almost all of them: the color.

The first industries that installed their treatment plants treated wastewater using physical-chemical systems of coagulation-flocculation, with high consumption of chemical and producing a great amount of sludges. These plants, if correctly designed and operated (which did not always happen) managed to eliminate the color, but in the water remained a very important organic charge that in general exceeded the legal limits of discharge to river.

A real scale study was sponsored by the ICAEN and performed together with the Polytechnic University of Catalonia and a textile company located in the upstream of river Llobregat, where conservation of the fish was an strategic action for the region located at the foot of the Pyrenees mountain range. The study consisted in the essay of combining a trickling filter biological system with plastic media BIOFILL® type A and the existing physical-chemical system.

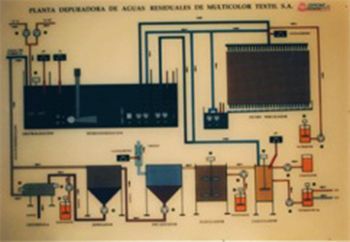

Flowsheet

Flowsheet View of trickling filter

View of trickling filter

The project consisted in introducing a trickling filter biological system equipped with PLASTIC MEDIA BIOFILL® type A; between the equalization tank and the existing physical-chemical system, the trickled water was sent to the homogenization tank activating it with enough air, from where the water was sent to the physical-chemical system. This combination supposed a drastic decrease of reactive consumption and therefore the diminishing of sludge production around 50% in volume.

General view of the modified plant

General view of the modified plant

The biomass that is formed in industrial wastewater treatment is completely different from the one that is formed in domestic wastewater treatment, firstly because the components to degrade are different and secondly because it takes the color of the water that is treated at the plant, and in the textile industry color may vary.The construction of the trickling filter does not need to be in concrete: The tank is filled with plastic, not water, so there is no side pushing in the walls, which can be as simple as the ones seen in this example. In this case the construction was done with stainless steel 304, but it can be in galvanized steel or glass-fused-to-steel, always depending on the budget that can be spent.

The success of the experience allowed not only to eliminate the color, but also over 93% of the dissolved organic load. This success lead to the construction of many other plants with this system in the textile sector.

Biofill A with residue

Biofill A with residueCONCLUSIONS

The result was spectacular by installing the trickling filter before the physical-chemical in all cases, activating equalization and from here feeding the physical-chemical. This allowed to:

- Eliminate the dissolved organic charge to limits that allowed to discharge the treated water to the river, meeting the regulation for specially protected areas.

- Reduce drastically the chemicals consumption.

- Reduce sludge production to less than a half.

- Reduce the operational costs to less than a half.

The filter media BIOFILL® type A installed for the projects has not needed to be replaced in any of the cases. Later on, this system has been usually used, not only in textile industry, but also in other industrial sectors.