Double moving bed high content nitrogen

Double moving bed high content nitrogen

DOUBLE MOVING BED TREATMENT SYSTEM (MBBR) FOR WASTEWATER WITH HIGH CONTENT OF NITROGEN AND BOD

In the last years, fix biomass moving bed reactors (MBBR), designed for wastewater treatment, ensure an efficient and total elimination of Kjeldahl nitrogen (NTK), biochemical oxygen demand (BOD) and total suspended solids (SS) either in municipal and industrial wastewaters.

INTRODUCTION

For example, one of the most difficult cases to treat is the processing of wastewaters coming from corral birds and other type of waters from cattle raising facilities slaughterhouses, because of the amount of grease and oils with high lipids content (FOG).

These activities imply a high water consumption, as it is typical of all food processing sectors. For chicken fattening, for example, between 19 and 38 liters (5-10 gal USA) of water are needed for a medium sized bird, about 2 kilograms. Is usual for a chicken processer to generate between 3.100 and 3.800 cubic meters (800.000 to 1.000.000 gal USA) of water per day. This water is charged with proteins, greases and carbohydrates from the flesh, blood, skin and feathers. Residual waters containing a high content of grease and oil can represent significant trouble for treatment. The effluent is also typically contaminated with a big amount of inorganic matter from grain and others. The same thing occurs with residual waters from slaughterhouses of other kinds of animals, with the common features of grease and oil content and the differences characteristic to each sector.

This type of wastewaters require treatment plants which are highly specialized and effective in order to eliminate most of this organic matter, dissolved or suspended in the residual waters, before they are discharged into the municipal sewage system or public stream, in order to achieve the accomplishment of the local, national and communitarian environmental regulations.

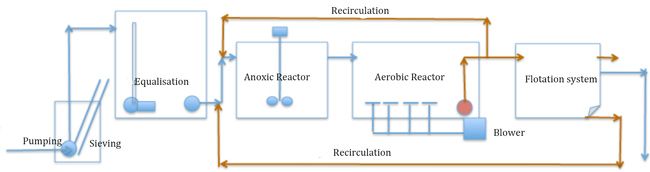

In order to achieve acceptable levels for total nitrogen and to process in an efficient way the high organic charge in the wastewaters, the water sector has developed a system for biological treatment in two phases with fix biomass moving bed (MBBR) on a plastic support with high specific surface (carrier), followed by a flotation process by dissolved air (DAF) or microfiltration system, in order to clarify the biological solids produced during the MBBR processes.

DESCRIPTION OF SYSTEME

MBBR use the advantages of activated sludges and fix biomass systems. The first phase (first MBBR) in the dual bioreactor process is designed to eliminate almost all nitrogen. Bacteria use the oxygen contained in the nitrates in an anoxic reactor, so nitrogen is released into the atmosphere.

The second phase (second MBBR) is used for BOD elimination.

Dual MBBR, which work at a temperature range between 15 and 30ºC, allow the growth of specialized bacteria in each reactor. In both reactors, reactions can be helped with the addition of specialized microorganisms.

High reductions of BOD have to be achieved in order to eliminate the constituents of ammonia/TKN, the organic BOD consuming bacteria have to be more than the nitrifying bacteria. In order to guarantee that ammonia reaches the effluent in a concentration that meets the standards, all BOD has to be removed.

The basis of the process are the biofilm-carrier elements, which are made from plastic material. BIOFILL® Type C, with high density (polyethylene or polypropylene) and high specific surface meets these requirements perfectly. These elements provide a large protected surface for the biofilm (as can be seen in the pictures that follow) and the optimal conditions for bacteria growth and for the degradation of BOD, NH3-N and NO3-N.

The transformation process occurs in serial phases, catalyzed by different enzymatic systems, with different intermediate products appearing during the process such as nitrites (NO2), oxide nitric and oxide nitros (NO).

This technology combines a completely open sole-biomass carrier with a highly efficient aeration and mixing design. This provides a superior effective surface area for biomass growth and optimal efficiency for oxygen transfer, and minimizes the secondary effects of mass transfer.

Biofilm protects the bacteria colonies from alterations of pH and temperature and from rough toxic entries, producing a very strong system although the fluctuations of the process.

The construction of the treatment plant requires about 30% less physical space (surface-volume) compared with other biological systems and many less control factors. The levels of nutrients and dissolved oxygen (DO) are the only control points needed for the system.

The aeration grid mounted in the low part of the aerobic reactor provides bacteria with the oxygen needed. The design of the panel provides the turbulence and mix needed to improve the oxygen mass transference and the flow of residual waters through the biofilm, creating optimal conditions for degradation of BOD, NH3-N or NO3-N. The design of the panel also supports the heavy weight of the biofilm carriers in the event the reactor has to be drained.

COMPLEMENTARY PROCESSUS TO BASIC INSTALLATION

Any biological process is more difficult with the presence of a high concentration of greases and/or oils. This inconvenience, which is usual in this kind of wastewaters, has to be solved before the biological processes. The system used until recently was the installation of a flotation primary system, but this system generates an amount of sludge that increases a lost the cost of exploitation for the plant. Currently this primary treatment is being substituted for biological products (BACTERIA® BIOPOP) which adsorb directly the greases and oils with a low cost.

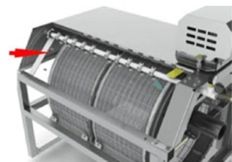

In MBBR, bacteria colonies digest the soluble organic compounds and slowly mature, releasing from the media and forming natural floccules. In order to provide an efficient elimination of the biomass and solids produced in the MBBR, a tertiary DAF system or a microgfilter is added to the MBBR to provide a complete treatment system.

Operational flexibility and efficiency

A control system integrating the functions of the MBBR with processes of the upstream and downstream plants uses a programmable logic controller (PLC) to control tightly the working parameters and the input taxes for chemical products in order to achieve highly consistent and quality effluent conditions. The control software provides the functionality to parameter the operating data.

It also allows the operators to control the system from a place with a HMI (man/machine interface) tactile board or even with a mobile phone. The plant can be controlled and locate breakdowns from remote places with Internet.

ESSENTIAL ELEMENTS FOR THE GOOD OPERATION OF SYSTEM

- The carrier of biomass grow : BIOFILL® TYPE C and C-2

- Biological products for help nitrification and denitrification BACTERIA® DEN

- Biological products for remove fat and oils: BACTERIA® BIOPOP

- Microfiltration system – flotation system.